Process

Forged Engineering Excellence.

Since 1989.

At NEX2UNE, our commitment extends beyond crafting wheels; we’re devoted to curating a lifestyle that mirrors a love for creativity and a commitment to delivering the finest wheels. A great wheel is defined by its performance and longevity, and that’s why we prioritize precision designing, meticulous engineering, and expert craftsmanship. Our goal is to attain the utmost quality in wheels within our class.

THE FOUNDATION OF NEX2UNE FORGED WHEELS

Phase 1:

ENGINEERING

Every collection of NEX2UNE Forged wheels undergoes a thorough design, engineering, and craftsmanship process at our Facility. With a team of over 100 professionals boasting over 50 years of collective forged wheel expertise, NEX2UNE Forged maintains complete control over the process’s quality. Each order undergoes testing to guarantee an optimal blend of lightweight design, durability, and strength.

Phase 2:

MATERIAL: 6061 T6 ALLOY FORGED

Incorporating APP raw forgings across our entire range of forged wheel collections. APP, known for producing forgings for the esteemed high-end automotive market, including brands like Aston Martin, Ferrari, Koenigsegg, Lamborghini, Mercedes AMG, Pagani, and Porsche, emerged as an ideal forging supplier for us.

Why forged?

Creating a one-piece forged wheel eliminates any chance of porosity. The world’s foremost aircraft manufacturers employ one-piece forgings for superior performance in vital structural applications. App Forged Wheels utilizes this same process, drawing upon over 50 years of experience in manufacturing aerospace and commercial forged products, to craft aluminum wheels. The outcome is a wheel that is both high-strength and lightweight, free from porosity and welded joints.

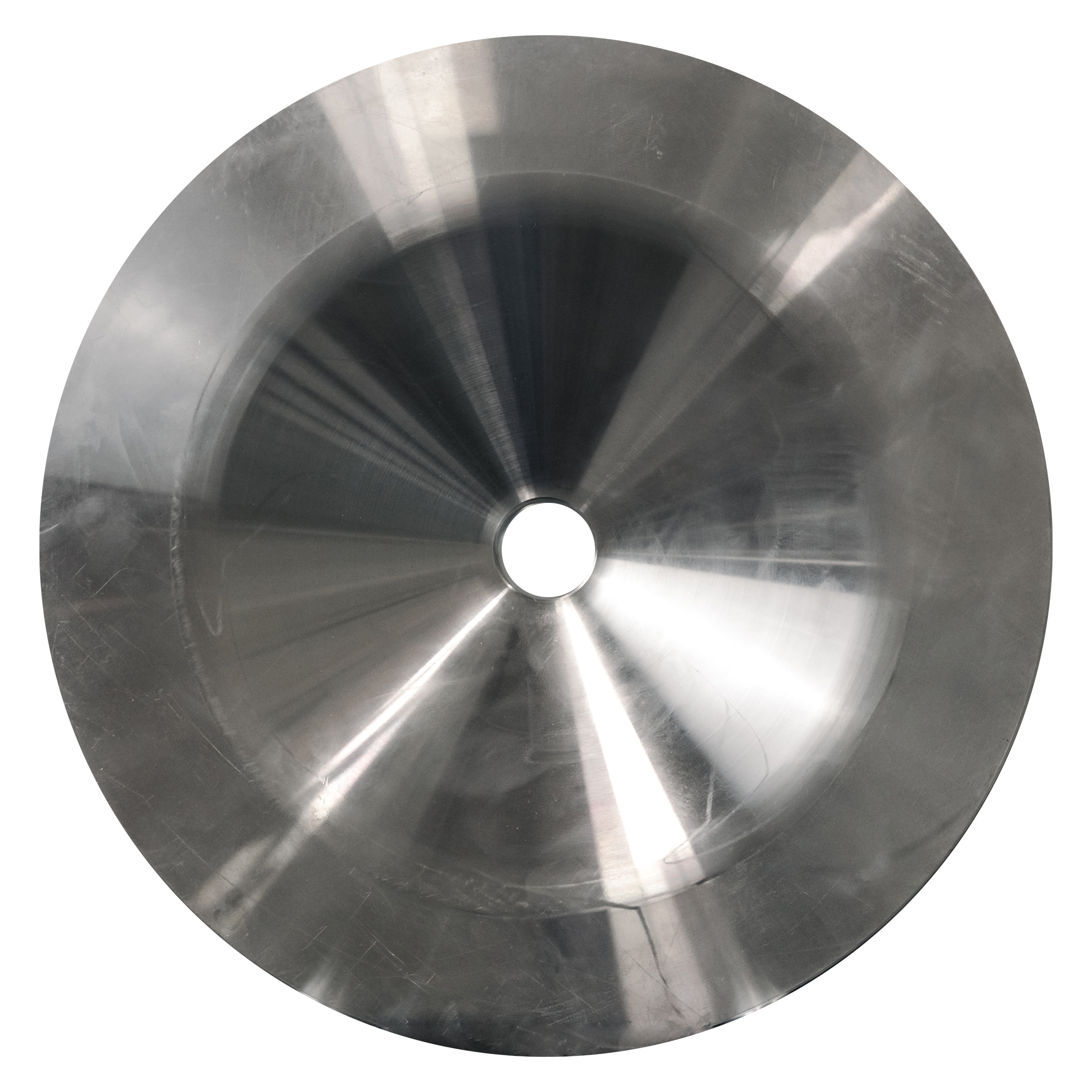

Wheel blank

The forging process employs elevated pressure and temperature to transform the non-directional grain structure of cast aluminum into the high-integrity multi-directional grain structure characteristic of forgings. Throughout this procedure, the aluminum maintains its solidity as forging dies converge, reshaping the round cast bar into the cylindrical form of a wheel. Subsequently, the forged wheel blank undergoes spin-forging in a specially designed machine, forging the rim section. The resultant radial grain direction aligns the highest material strength with the operating loads, resulting in what we term “premium strength.”

Strength

Load ratings can vary, starting as low as 1500 pounds for racing and sports car applications, reaching up to 3,500 pounds for light trucks, SUVs, off-road applications, and even higher for commercial vehicles. These load ratings undergo verification through a series of cornering fatigue, radial fatigue, and impact tests.

One added advantage of Forged Wheels, upon request, is a polished mirror finish. This is made possible by the exceptional integrity of the metallic structure achieved through the forging process. Each Forged Wheel is meticulously crafted from the highest quality 6061 T6 alloy.

Phase 3:

LATHE TURNING

A pivotal step in forging wheel production is the process of lathe turning. The raw forging undergoes lathe turning from both the front and rear, shaping a profile that accentuates concavity. During this step, more than 70% of the initial material is removed, resulting in optimal weight reduction.

TOOLS:

Vibration Reduction Tools – To achieve more precise machining tolerances and smoother finishes, we’ve opted for Sandvik®, a leading German manufacturer renowned for producing the finest lathe tools in the industry. Employing their exclusive Silent Tools™ Anti-Vibration Technology, this innovation enables our production to eradicate vibrations that might otherwise result in poor surface texture and inadequate accuracy.

Wireless Intuitive Probing System – (WIPS) simplifies the job setup process, guiding the operator and minimizing setup time by allowing multitasking while automatic probing routines run. WIPS ensures that tools and parts maintain tolerance levels throughout the entire production process.

Phase 4:

QUALITY CONTROL

After turning, testing and each center undergoes a meticulous remeasurement and is subjected to a quality control checklist. This ensures that every part aligns with our standards and tolerances before the milling process commences.

Phase 5:

MILLING

This is where design meets reality and comes to life.

Once the profile is completed, the forgings are then turned over to the mill process. The mill process is where the design comes to life. As mill cycles run through a series of pre-selected tool sets and milling paths that can take up to 8 hours per wheel to achieve the utmost precision.

After the milling process is completed, each section of raw milled aluminum needs to go through many stages of

- Hand Filing,

- Deburring,

- Buffing and Ceramic Bead High-Luster Polishing

before it is ready for its ultimate finish.

This is a vital stage for our craftsmen to prep each wheel before its coating. After each wheel is filed and sculpted the wheels go through a detailed check list with zero compromises.

HIGH-VELOCITY MACHINING:

Our domestically produced High-Performance Super-Speed vertical CNC machinery boasts elevated spindle speeds, swift rapids, and rapid tool changes, essential for guaranteeing quicker lead times.

REDUCING WEIGHT:

All current designs incorporate Scallop Undercutting, effectively decreasing the overall weight and unsprung mass of every wheel we produce. The scalloping of spoke sides forms an “I-Beam” cross-section along its length, optimizing strength-to-weight ratio. Additionally, each design has been standardized with Through-Hub Pockets placed between the lug holes, enhancing heat dissipation efficiency and diminishing unsprung mass/weight on the wheel hub. The designs are available in five distinctive build configurations, sharing and personalizing newly developed details.

ROTATING BENDING TESTING:

The rotating bending test is a fatigue evaluation method that assesses the wheel’s resistance by applying a rotating bending moment generated through a rotating unbalanced mass. This test replicates the load conditions experienced by the wheel during regular use, with the primary stresses concentrated in the central part of the wheel.

In late 2016, the bending test machines underwent a retrofitting process, resulting in:

– Enhanced control facilitated by a parameter data acquisition system with an increased sampling frequency.

– Improved time history capabilities, enabling the storage of parameters and test data throughout the entire test performance.

– Enhanced precision of the wheel bending measuring system.

– Increased data safety

Phase 6:

PREPARATION, HIGH LUSTER CERAMIC POLISHING & BRUSHING

Prep: The most meticulous, albeit time-intensive, stage of the finishing process involves brushing and polishing. Available as upgraded options in every NEX2UNE Forged wheel collection, brushed wheels showcase the exquisite details in the forged aluminum grain, while touchless high-luster ceramic polishing yields a mirror-like finish.

Polishing: Crafting the wheel as a single forged piece eradicates any chance of porosity. The foremost aircraft manufacturers globally opt for one-piece forgings due to their exceptional performance in crucial structural applications. App Forged Wheels employs the same method, leveraging over 50 years of experience in manufacturing aerospace and commercial forged products, to create aluminum wheels. The outcome is a wheel that is both high-strength and lightweight, devoid of porosity and welded joints.

Brushing: The forging process uses high pressure and temperature to change the non-directional grain structure of the cast aluminum starting material to the high integrity multi-directional grain structure of forgings. The aluminum remains solid throughout the process as the forging dies come together and change the shape of the round cast bar to the cylindrical shape of a wheel. The forged wheel blank is then placed in a custom built spin-forging machine to spin out and forge the rim section. The resulting radial grain direction places the highest material strength in the same direction as the operating loads. The result is “premium strength”.

Phase 7:

FINISHING TOUCHES

The most gratifying phase of the manufacturing process is the finishing stage. NEX2UNE premium finishes presents a brushed or polished base complemented by transparent powder coats, unveiling the intricacies and beauty in the design. At NEX2UNE we continually explore innovative methods to achieve the most stunning finishes. Each wheel component is available with a Gloss, Satin, or Texture finish of your preference.

Phase 8:

ASSEMBLY

The assembly stage stands out as one of the most crucial phases in the manufacturing process. The initial step involves checking the run-out of each wheel to ensure balanced wheels, eliminating vibrations and wobbling. We’ve opted for Digital Snap-On® Torque Wrenches over generic torque wrenches for precise control over applied torque without compromising torque capacity.

To maintain accuracy and safety, we calibrate our wrenches annually or after 5,000 cycles. Following the torquing of each bolt and nut, we mark them, and our expert assemblers sign off on the wheels before they are packaged.

On all orders

Offered in the country of usage

PayPal / MasterCard / Visa / AMEX